Leadership

Lachlan Miegel

Team Lead

Charles Herman

Chief Engineer

Will Borden

Lead Systems Engineer

Jemima Harman

Head of Business

Our Sub-teams

Aerostructures

Team Leads: Jules Seng, Alexandra Margiolis, Ennis Wong

The Aerostructures team designs and manufactures the rocket's airframe and internal structural components. The team combines aerodynamic analysis and mechanical design to develop and produce critical parts such as the nose cone, boat tail, and bulkheads. This involves tasks ranging from Computational Fluid Dynamics (CFD) and Computer-Aided Design (CAD) to Structural Simulation and hands-on Manufacturing.

Past projects include the simulation of air brakes at various extensions to determine their drag profile, the development of retractable rail guides, and a resin-infused fiberglass recovery parachute compartment.

Core Responsibilities

- Computational Fluid Dynamics (CFD): Optimising aerodynamic surfaces for stability and drag reduction, alongside flow visualisation and modelling the rocket’s drag curve

- Airframe Development: Using CAD and simulation tools to iterate the overall rocket design to align with competition parameters

- Internal Components: Liaising with other sub-teams to understand structural requirements, complete CAD modelling, and conduct Finite Element Analysis (FEA) to validate strengths

- Research and Development Projects: Investigating ways to advance Aerostructures design and manufacturing capabilities, such as improving CFD modelling techniques and developing new composite manufacturing methods

- Manufacturing: Fabricating parts using composite techniques such as resin infusion, and CNC processes to build the competition rocket

Team members collaborate closely and gain exposure to all skills throughout the full lifecycle of design, validation, and production. From CFD simulations to composite manufacturing, Aerostructures works across a range of mechanical engineering disciplines and fundamentals.

Propulsion

Team Leads: Brooke Doolan, Steven Wang

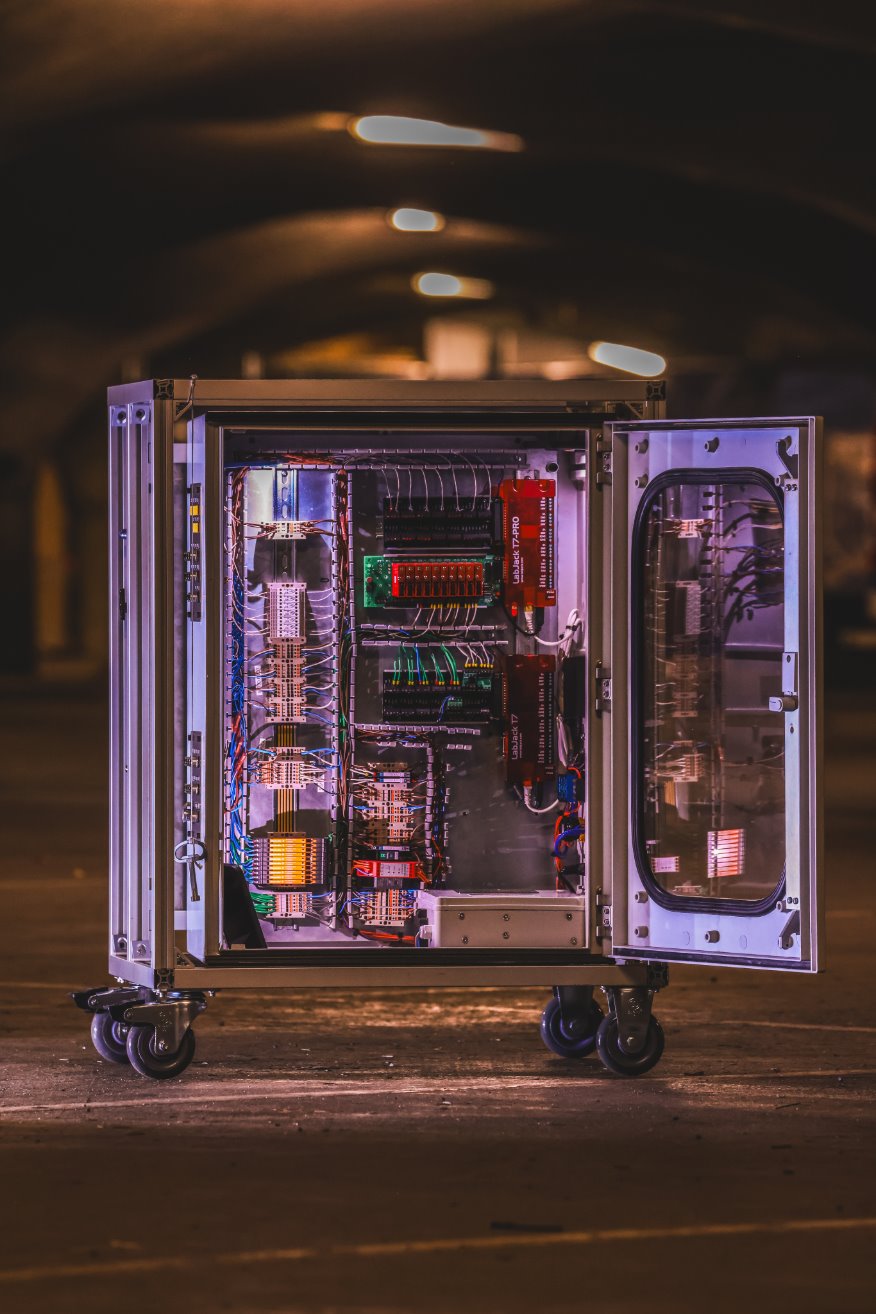

The Propulsion team is responsible for the end-to-end design, development and testing of student-built rocket engines. This includes everything from subscale hardware to full-scale hybrid systems ready for flight integration. Previously, the team developed a sub-scale test stand, Data Acquisition (DAQ) & Control cabinet, and fluid system. The current focus is on hot fire testing and building the first ARES full-scale hybrid rocket engine for integration into a launch vehicle by the end of 2026.

Core Responsibilities

- Full-scale Test Stand Development: Design, manufacture and assemble static fire infrastructure and support equipment

- DAQ & Control: Integration of sensors, actuators, safety mechanisms and real-time control software for test operations

- Fuel Grain Manufacturing: Spin-casting paraffin wax-based fuels and experimenting with additives to improve performance

- Fluid Systems: Designing, building and testing high-pressure liquid & gas systems with safe operation

- Combustion Chamber Design: Thermo-fluid analysis and simulation of chamber and nozzle performance

- Modelling & Simulation: Development of analytical and computational models to predict engine behaviour and guide design decisions

Avionics

Team Lead: Joshua Vaughan

Sub

Leads: Lachlan Power, Auriella Fisher, Nicholas Cotugno Morrison

The Avionics team develops and integrates electronic systems for both the rocket and its ground support equipment. At the core of these systems is the ARES Compute Platform, a fully interconnected system spanning hardware design, embedded software, ICT infrastructure, and web development. The team is currently developing a 2nd generation in-house flight computer with complimenting web platform for real time control, and flight data visualisation.

Core Responsibilities

- Rocket Avionics: Develop and program embedded avionics systems, including telemetry, radio communications, active aero controllers, data logging, and power management systems.

- Ground Station: Integrate ground support equipment and ICT infrastructure with rocket avionics, and DSLR camera.

- Data: Develop a Web interface for real time control, and flight data visualisation tools, and develop existing airbrake control systems.

Recovery

Team Leads: Caroline Berg, Jeet Bhandari

The Recovery team aims to achieve the safe descent and retrieval of the rocket, from altitudes up to 30,000 feet. Currently, the team has developed a single-separation, dual-deployment scheme featuring a CO2 separation system, with a 3-ring release mechanism, and line cutters for precision ejection of the parachutes.

Currently, the team is focusing heavily on designing and researching an improved recovery system. The new system will build on the existing foundation, concentrating on creating reliable and mechanically sound infrastructure for future rockets. Furthermore, we’re constantly improving our ability to manufacture components such as deployment bags, with a focus on creating in-house parachutes.

Core Responsibilities

- Mechanical System Design: CAD creation of systems such as line cutters, CO2 ejection parts, and other flight-critical recovery components

- Hands-on Fabrication: Sewing and creation of parachute and deployment assemblies

- Results Synthesis: MATLAB scripting and data analysis

- Real-World Applications: Continual hands-on testing and field deployment of recovery system

Payload

Team Lead: Charlton Hammond

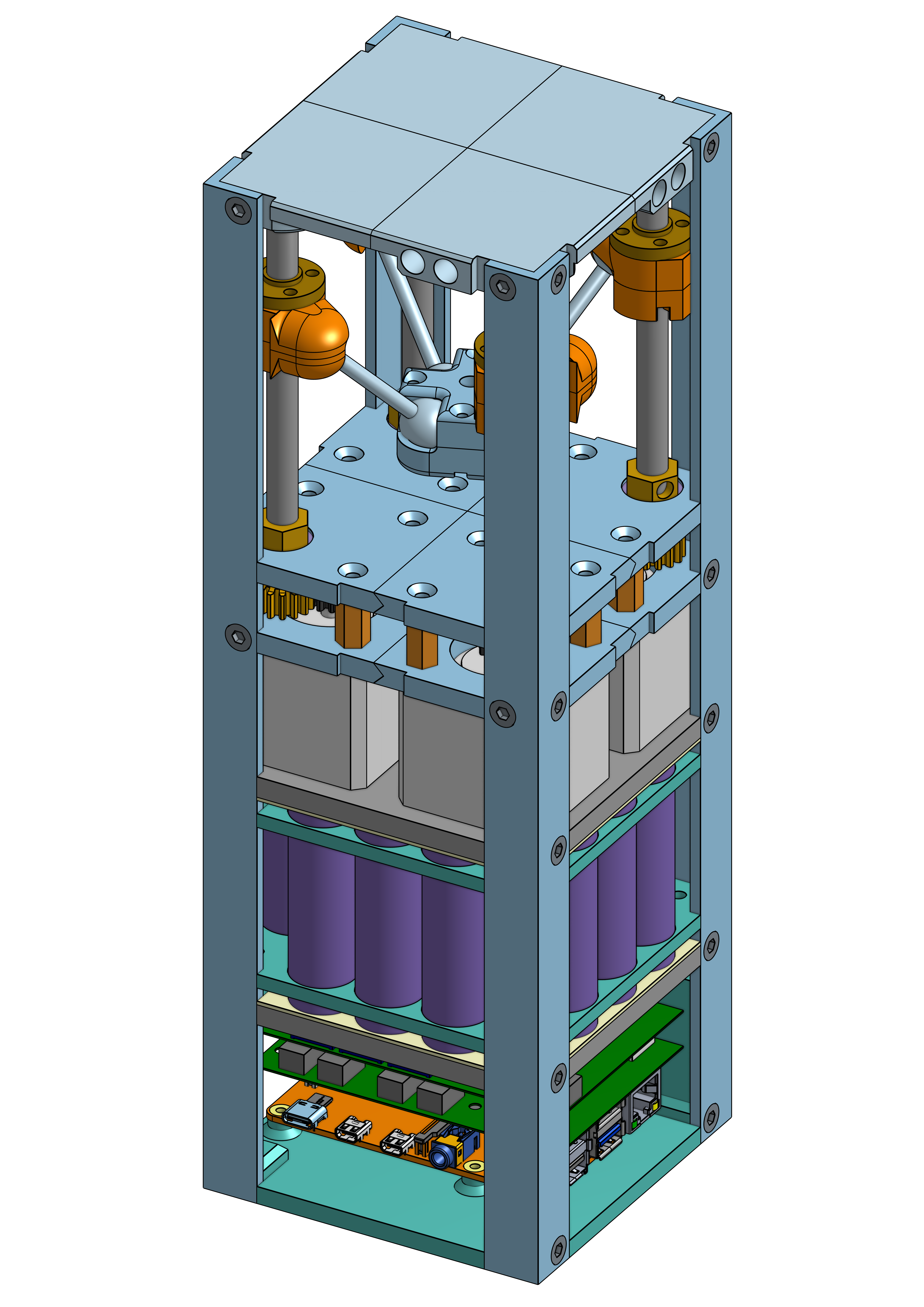

The Payload team develops an experimental scientific payload that rides on the competition rocket, investigating technologies relevant to space applications.

Previous payloads have included an award-winning investigation into the effects of high acceleration flight on bacteria using Raman spectroscopy, and creating a surgical robotic arm that can perform high-precision surgery under high acceleration flight using a quad-arm control mechanism.

Core Responsibilities

- Electronic Design: PCB development for sensor integration and power management utilising Altium

- Mechanical and Structural Design: Using CAD software to design, prototype, and analyse the payload

- Manufacturing and Testing: Including metal work, soldering and 3D printing

- Software Design: Writing code to communicate with and control the various sensors and actuators, perform data processing, and wireless communication

Operations & Logistics

Team Lead: Amelia Liu

The Operations & Logistics sub-team drives the strategic coordination and operational execution of the team's initiatives. This sub-team ensures that ARES operates efficiently, fosters external partnerships that are essential to the construction of the rocket, and effectively communicates the team's endeavours and knowledge to relevant stakeholders.

Core Responsibilities

- Stakeholder and Partnership Engagement: Securing and maintaining sponsorships with new and existing partners

- Logistics Organisation: Planning logistics for travel and competition entry

- Internal Collaboration: Liaising with the Faculty of Engineering & Information Technology

- Merchandising: Designing and producing team merchandise

- Videography and Marketing: Managing social media, filming, editing videos, and creating promotional materials